I-SDY630/400 BUTT FUSION OPERATION IMANUAL

Ibanga elisebenzayo kanye nepharamitha yobuchwepheshe

| Uhlobo | SDY-630/400 |

| Izinto zokwakha | I-PE, PP kanye ne-PVDF |

| Ibanga lobubanzi | 400㎜~630㎜ |

| Izinga lokushisa le-ambient. | -5~45℃ |

| Ukunikezwa kwamandla kagesi | 380 V±10%, 50Hz |

| Amandla aphelele | 12.2 Kw |

| Faka: I-Heating plate | 9.2kw |

| Ithuluzi lokuhlela | 1.5kw |

| Iyunithi ye-hydraulic | 1.5kw |

| Ubukhulu. Ingcindezi | 6.3 Mpa |

| Ingxenye ephelele yamasilinda | 23.06 cm2 |

| Amafutha weHydraulic | YA-N32 |

| Ubukhulu. Izinga lokushisa | <270℃ |

| Umehluko wokushisa we-heater plate interface | ±7℃ |

| Isisindo esiphelele, Kg | 635 |

Incazelo ekhethekile

Sincoma ukuthi ufunde wonke umbhalo ngokucophelela ukuze uqinisekise ukuphepha komsebenzisi nokokusebenza ngaphambi kokuqala ukusebenzisa umshini. Le manuwali yokusebenza kufanele igcinwe ngokucophelela ukuze isetshenziswe esikhathini esizayo.

3.1 Lo mshini awuhambisani nokushiselwa kwamapayipi okungachazi; ngaphandle kwalokho kungalimaza noma kwenzeke ngengozi.

3.2 Ungawusebenzisi umshini endaweni yengozi yeziqhumane.

3.3 Umshini kufanele usetshenziswe ngu-opharetha oqeqeshiwe.

3.4 Umshini kufanele usebenze endaweni eyomile. Izinyathelo zokuzivikela kufanele zithathwe lapho isetshenziswa emvuleni noma emhlabathini omanzi.

3.5 Amandla okokufaka angu-380V±10%, 50Hz. Uma kusetshenziswa umugqa wokufaka onwetshiwe, umugqa kufanele ube nesigaba sokuhola esanele.

IziceloIncazelo yezingxenye

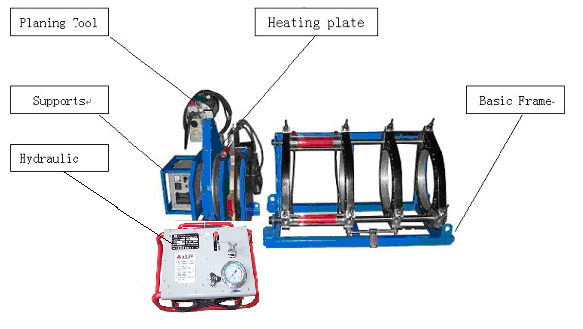

Umshini wakhiwe ngohlaka oluyisisekelo, iyunithi ye-hydraulic, ipuleti lokushisa, ithuluzi lokuhlela, ukusekelwa kwethuluzi lokuhlela kanye nebhokisi likagesi.

4.1 ukucushwa komshini

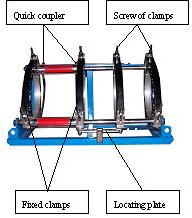

4.2 Uhlaka oluyisisekelo

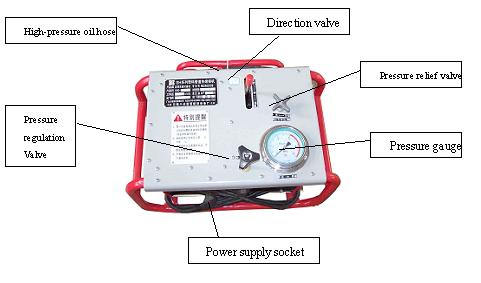

4.3 i-hydraulicamayunithi

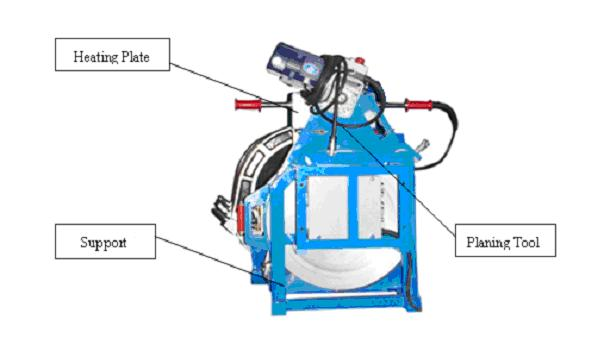

4.4 Ithuluzi lokuhlela kanye ne-heater plate

Umyalelo wokusetshenziswa

5.1 Zonke izingxenye zemishini kufanele zibekwe endizeni ezinzile neyomile ukuze zisebenze.

5.2 Qinisekisa amandla ngokomshini wokuhlanganisa izinqe oceliwe, umshini usesimweni esihle, intambo kagesi ayinqamuki, zonke izinsimbi zivamile, izindwani zethuluzi lokuhlela zibukhali, zonke izingxenye ezidingekayo namathuluzi kuphelele.

5.3 Uxhumano lwe-hydraulic nogesi

5.3.1 xhuma uhlaka oluyisisekelo neyunithi ye-hydraulic nge-coupler esheshayo.

5.3.2 xhuma ulayini wepuleti lokushisisa ebhokisini likagesi kuhlaka oluyisisekelo.

5.3.3 xhuma ulayini wepuleti lokushisisa nepuleti lokushisisa.

5.3.4 Faka izinto ezifakwayo ngokobubanzi obungaphandle bepayipi/ukufakwa kuhlaka oluyisisekelo.

5.4 Inqubo yokushisela

5.4.1 Hlola ububanzi nobukhulu bodonga noma i-SDR yamapayipi/izinto zokufakwa ezizoshiselwa ukuthi zilungile. Ubuso bayo kufanele buhlolwe ngaphambi kokuqala ukushisela, uma ukuklwebheka kudlula u-10% wodonga oluwugqinsi, kufanele kusikwe ngokwengxenye ukuze kusetshenziswe.

5.4.2 Hlanza indawo yangaphakathi nangaphandle yepayipi ukuze lishiselwe.

5.4.3 Faka amapayipi/izixhumi ezintweni ezifakwayo zefreyimu, ubude bamapayipi/izifakelo ekugcineni ezizoshiselwa ngaphandle kokuzifaka mhlawumbe ziyafana (mafishane ngangokunokwenzeka). Esinye isiphetho sepayipi kufanele sisekelwe ngama-roller ukunciphisa ukungqubuzana. Bese usififulela isikulufu sezinsimbi ukuze ubambe amapayipi/ukufaka.

5.4.4 Faka ithuluzi lokuhlela ohlakeni phakathi kwamapayipi/izinsimbi bese uyavula, vala iziphetho zamapayipi/izixhumo ngokusebenzisa ivalvu eqondisa ukusebenza kweyunithi ye-hydraulic kuze kube yilapho sekuvela ukushefa okuqhubekayo kuzo zombili iziphetho.(ingcindezi yokushefa ingaphansi kuka-2.0 Mpa). Beka ibha yevalvu yokuqondisa endaweni emaphakathi futhi ugcine imizuzwana embalwa, bese uvula ifremu, uvale ithuluzi lokuhlela futhi ulikhiphe ngaphandle kohlaka. Ubukhulu be-shavings kufanele bube ngu-0.2 ~ 0.5 mm futhi bungalungiswa ngokulungisa ukuphakama kwezindwani zamathuluzi okuhlela.

5.4.5 Vala ipayipi/iziphetho zokufaka bese uhlola ukungahambi kahle kwawo. Ubuningi. Ukungalungi kahle kahle akumele kudlule u-10% wokuqina kodonga, kungathuthukiswa ngokulungisa ukuqondisa kwepayipi futhi kuxegiswe noma kuqinise izikulufo zokudonsa. Igebe phakathi kweziphetho zamapayipi amabili akufanele lidlule u-10% wokuqina kodonga, noma kufanele linqunywe futhi.

5.4.6 Sula uthuli futhi uhlale ku-heater plate (Ungaklwebhi ungqimba lwe-PTFE phezu kwepuleti lokushisa).

5.4.7 Faka ipuleti lokushisisa ohlakeni phakathi kwamapayipi ngemva kokufika kwezinga lokushisa elidingekayo. Phakamisa ingcindezi ifike edingekayo kuze kube yilapho ubuhlalu bufinyelela ukuphakama okufanele.

5.4.8 Yehlisa ingcindezi enanini elanele ukugcina iziphetho zombili zamapayipi/izixhumo zithintana nepuleti yokushisisa ngesikhathi sokucwiliswa esidingekayo.

5.4.9 Uma isikhathi sesifikile, vula ifremu bese ukhipha i-heater, vala iziphetho ezimbili ezincibilikayo ngokushesha okukhulu.

5.4.10 Khulisa ingcindezi ifike kumfutho wokushisela futhi ugcine ilunga libe yisikhathi sokupholisa. Yehlisa ingcindezi, khulula isikulufu sezinsimbi bese ukhipha ipayipi elihlangene.

Ithuluzi lesikhathi

Uma enye ipharamitha ishintshiwe, njenge-diameter engaphandle, i-SDR noma impahla yepayipi, ukucwiliswa ngesikhathi sokushisa nesikhathi sokupholisa kufanele kusethwe kabusha ngokwezinga lokushisela.

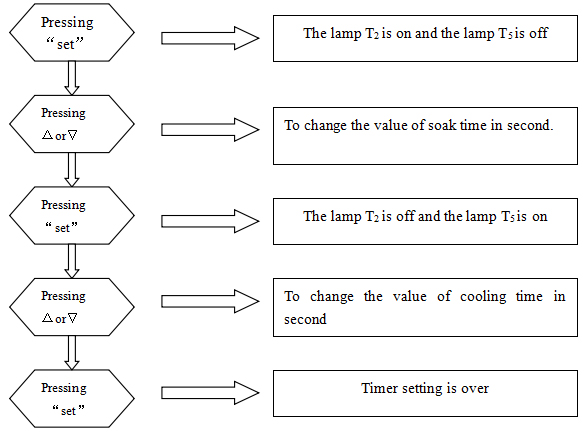

6.1 Ukusetha isikhathi

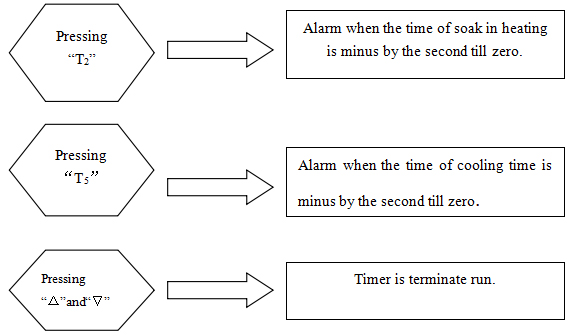

6.2 Umyalelo Wokusetshenziswa

Welding standard kanye isheke

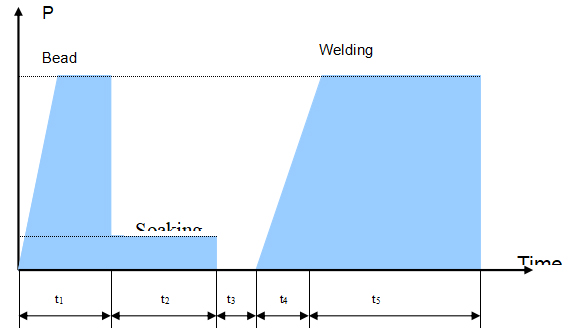

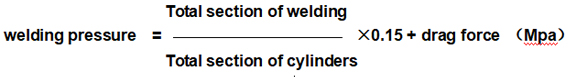

7.1 Ngenxa yezinga elihlukile le-welding kanye nezinto ze-PE, isikhathi nokucindezela kwesigaba senqubo ye-butt fusion kuhlukile. Iphakamisa ukuthi amapayipi kufanele afakazele imingcele ye-welding yangempela kanye nokwakhiwa kokufakwa.

7.2 Izinga lokubhekiselaI-DVS2207-1-1995

| Ukujiya kodonga (mm) | Ubude be-bead (mm) | Ingcindezi yobuhlalu (Mpa) | Isikhathi sokucwilisa t2(Isekhondi) | Ukucwiliswa kwengcindezi (Mpa) | Ukushintsha kwesikhathi t3(Isekhondi) | Isikhathi sokukhuphuka t4(Isekhondi) | Ingcindezi yokushisela (Mpa) | Isikhathi sokupholisa t5(imizuzu) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70 - 120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45; 60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20 - 25 | 25-35 | 0.15±0.01 | 60-80 |

Phawula:

Izinkulumo:

Ukuqhubeka kwesikhangiso sokuphepha

Kunconywa kakhulu ukuthi ufunde futhi ulandele ngokucophelela le mithetho elandelayo ngokuphephile ngaphambi kokusebenzisa umshini.

8.1 Abasebenzi bamakhono kufanele baqeqeshe ngaphambi kokusebenzisa nokusebenzisa umshini.

8.2 Umshini kufanele uhlole futhi ulungise futhi usebenzise eminyakeni emibili edlule ohlangothini oluphephile.

8.3 Amandla: Ipulaki yokuphakela amandla ihlinzekwa nomthetho wokuphepha kwabasebenzisa amakhono kanye nokuphepha komshini.

Isilungiselelo esiphephile kufanele sibe negama noma umfanekiso ukuze kubonakale.

Xhuma ngomshini namandla: Amandla okufaka angu-380±20V we-50Hz. Uma kusetshenziswa umugqa wokufaka onwetshiwe, umugqa kufanele ube nesigaba sokuhola esanele.

I-Grounding: Kumelwe ibe nesignali yokudlulisela yolayini esizeni sokwakha, ukumelana nesisekelo kuhambisana nesilungiselelo sokuvikela futhi siqinisekise ukuthi akudluli ama-voltage angama-25 nokusetha noma ukuhlolwa ngosebenza ngogesi.

Isitoreji sikagesi: Umshini kufanele usebenzise isitoreji ukuze uqinisekise ukuphepha.

Xhuma ngomshini kufanele uthintane nomthetho osebenzayo.

※ Gwema noma yiluphi uhlobo lwengozi ebangelwa ugesi.

※ Gwema ukunqamula ukunikezwa kwamandla ngokuhudula

※ Gwema ukunyakaza, hudula futhi ubeke umshini ngomugqa wekhebula.

※ Gwema umphetho kanye nesisindo kulayini wekhebula, izinga lokushisa lolayini wekhebula akufanele lidlule u-70℃.

※ Umshini kufanele usebenze endaweni eyomile. Izinyathelo zokuzivikela kufanele zithathwe lapho isetshenziswa emvuleni noma emhlabathini omanzi.

※ Indawo yokusebenza kufanele ihlanzeke.

※ Umshini kufanele uhlolwe futhi ulungise isikhathi sesikhathi.

※ Ngezikhathi ezithile ulayini wekhebula we-insulation kufanele uhlole futhi ucindezelwe ngokukhethekile

※ Kuyingozi kakhulu ukusebenzisa umshini uma kunemvula noma izimo zikakolweni.

※ I-Residual yamanje ye-circuit breaker kufanele ilungiswe ngenyanga.

※ Osebenza ngogesi kufanele ahlole ukuthi isimo sinjani.

※ Uma uhlanza umshini ngokucophelela, ungafaki intulation yomshini noma usebenzise i-benzine, ukukhulelwa nokunye.

※ Umshini kufanele ugcinwe endaweni yokususwa kwesimo.

※ Wonke amapulaki kufanele axhumeke kugesi.

※ Ukusetshenziswa kwemishini edlule, umshini kufanele uhlale usesimweni esihle sokusebenza.

Kusikisela ukufunda nokulandela ngokucophelela imithetho ngokuphepha ngaphambi kokusebenzisa umshini.

Ingozi yokuqalisa: ngaphambi kokuthi umshini usebenze, ipulaki yokuphakela amandla ihlinzekwa ngokuphepha.

Amapayipi abekwe emshinini:

Beka amapayipi ku-clamps futhi uwabophe, ibanga lamapayipi amabili ekupheleni kufanele ufake ithuluzi lokuhlela futhi uqinisekise ukusebenza, ugweme noma yiluphi uhlobo lwengozi ebangelwa ugesi kanye nokusebenza.

Ukusebenza kwesimo:

Indawo yokusebenza kufanele ihlanzeke, yome futhi ikhanyiswe ngokufanelekile.

Kuyingozi kakhulu ukusebenzisa umshini uma lina noma izimo zikakolweni noma eduze noketshezi oluvuthayo.

Qaphela ukuthi bonke abantu abaseduze nomshini bakude nokuphepha.

Izingubo:

Gcina ukunakekelwa okuphezulu ngenkathi usebenzisa umshini ngenxa yezinga lokushisa eliphezulu elibandakanyeka kupuleti lokushisisa njalo lingaphezu kuka-200℃, kuphakanyiswa ngokuqinile ukusebenzisa amagilavu afanelekile. Gwema izingubo ezinde futhi ugweme namasongo, imigexo engase iboshwe emshinini.

Qaphela ingozi futhi uvimbele izingozi

Umshini wokuhlanganisa izinqe:

Ukusetshenziswa komshini kufanele kwenziwe ngamakhono asebenzayo.

※ Ipuleti lokushisisa

Ipuleti lokushisa ngenxa yokushisa okuphezulu okungaphezu kuka-270 ℃, kuphakanyiswa ukuthi kuthathwe isilinganiso:

---sebenzisa amagilavu ezinga lokushisa eliphezulu

---ngemuva kwepayipi lokuhlanganisa izinqe elinepayipi, ipuleti lokushisisa kufanele lifakwe.

---iqedile ipuleti lokushisisa kufanele libe phezu kwebhokisi.

---ivunyelwe ukuthi ingathinti ipuleti lokushisisa.

※ Ithuluzi lokuhlela

---ngaphambi kokusebenza kwe-Scraping, amapayipi nomhlabathi ukugwema ukungcola amapayipi abheke phezulu kuyaphela.

---iqedile ithuluzi lokuhlela kumele libe ku-Support for planing tool & heat plate

※ Uhlaka oluyisisekelo

---iqale ngaphambili ukuthi ifreyimu eyisisekelo ekuhlanganiseni okukhulunywe ngakho ngenhla Ilungele zonke izinhlobo zamapayipi ukuya ekushiseleni amapayipi.

--- ngenkathi uqala ukusebenza qaphela ukugwema ukushiya imilenze noma izingalo ezinyakazayo. Kuyimpoqo ukuba kude nohlaka oluyisisekelo.

---qaphela ukuthi bonke abantu abaseduze nomshini basebangeni lokuphepha.

---abaqhubi bamakhono kufanele bagcine imithetho yokuphepha.

Isondlo

| Into | Incazelo | Hlola ngaphambi kokusetshenziswa | Inyanga yokuqala | Njalo ezinyangeni eziyisi-6 | Njalo ngonyaka |

| Ithuluzi lokuhlela | Faka esikhundleni i-blade noma ushaye futhi Hlola ukuthi ikhebula beliphukile yini Hlola ukuthi uxhumano lwemishini luxegisiwe yini |

●

|

● |

| ● ●

|

| Ipuleti lokushisisa | Hlola ikhebula namajoyinti esokhethi Hlanza indawo yepuleti lokushisisa, gcoba kabusha ungqimba lwe-PTFE uma kunesidingo Hlola ukuthi uxhumano lwemishini luxegisiwe yini | ● ●

|

● |

|

●

|

| Isistimu yokulawula izinga lokushisa | Hlola inkomba yezinga lokushisa Hlola ukuthi ikhebula beliphukile yini |

● |

|

| ● ● |

| Uhlelo lweHydraulic | I-Checkout pressure gauge Hlola ukuthi ipayipi likawoyela livuzile yini, qinisa futhi noma kushintshwe izigxivizo Hlanza isihlungi Bheka amafutha uma engekho Shintsha amafutha Bheka ukuthi ipayipi likawoyela liphukile yini |

●

●

● |

|

●

| ●

● ●

|

| Okuyisisekelo Uhlaka | Hlola ukuthi isikulufu sokuqinisa ekugcineni kwe-eksisi yozimele besixegisiwe yini Fafaza upende we-antirust futhi uma kunesidingo |

●

|

●

|

●

|

● |

| Amandla Ukunikezela | Cindezela inkinobho yokuhlola yesivikeli sesekhethi ukuze uhlole ukuthi isivikeli sesekethe sisebenza ngokujwayelekile Hlola ukuthi ikhebula beliphukile yini | ● ● |

|

● |

|