I-SDY355 BUTT FUSION WElding MACHINE OPERATION IMANUAL

Incazelo ekhethekile

Ngaphambi kokusebenzisa umshini, noma ubani kufanele afunde le ncazelo ngokucophelela futhi ayigcine kahle ukuze aqinisekise ukuphepha kwesisetshenziswa nesisebenzisi, kanye nokuphepha kwabanye.

2.1 Umshini usetshenziselwa ukushisela amapayipi enziwe nge-PE, PP, PVDF futhi awukwazi ukusetshenziselwa ukushisela izinto ngaphandle kwencazelo, ngaphandle kwalokho umshini ungase ulimale noma kwenzeke ingozi ethile.

2.2 Ungawusebenzisi umshini endaweni enengozi yokuqhuma

2.3 Umshini kufanele usebenze ngabasebenzi abanomthwalo wemfanelo, abaqeqeshiwe nabaqeqeshiwe.

2.4 Umshini kufanele usebenze endaweni eyomile. Izinyathelo zokuzivikela kufanele zithathwe uma isetshenziswa emvuleni noma emhlabathini omanzi.

2.5 Umshini usebenza ngo-220V±10%, 50Hz. Uma kufanele kusetshenziswe ucingo olunwetshiwe, kufanele lube nesigaba sokuhola esanele ngokuya ngobude baso.

2.6 Ngaphambi kokusebenzisa umshini, gcwalisa 46# uwoyela wehydraulic. Qinisekisa ukuthi uwoyela we-hydraulic wanele ukusebenza; izinga lamafutha kufanele libe ngu-2/3 wethangi. Miselela isivalo sethangi likawoyela wensimbi ngekepisi ebomvu yepulasitiki yokopha umoya noma ingcindezi ayikwazi ukubamba.

Ukuphepha

3.1Nakekela lapho usebenzisa futhi uthutha umshini ngokuya ngayo yonke imithetho yezokuphepha kulo myalelo.

3.1.1 Qaphela uma usebenzisa

l Umsebenzisi kufanele abe ngabasebenzi abaqotho nabaqeqeshiwe.

l Hlola ngokuphelele futhi unakekele umshini ngonyaka ukuze uthole ukuphepha kanye nokwethembeka komshini.

l Indawo yokusebenza engcolile futhi egwadule ngeke nje yehlise ukusebenza kahle, kodwa ibangele ingozi kalula, ngakho-ke kubalulekile ukugcina indawo yokusebenza ihlanzekile futhi kungekho ezinye izithiyo.

3.1.2 Amandla

Ibhokisi lokusatshalaliswa kukagesi kufanele libe nesiphazamisi esinephutha eliphansi elinezinga elifanele lokuphepha kukagesi. Wonke amadivaysi okuvikela ukuphepha aboniswa ngamagama aqondakala kalula noma amamaki.

Earthing: Isayithi yonke kufanele yabelane ngentambo yaphansi efanayo futhi uhlelo lokuxhuma phansi kufanele luqedwe futhi luhlolwe abantu abangochwepheshe.

3.1.3 Ukuxhunywa komshini emandleni

Umshini wokuxhuma ikhebula emandleni kufanele ube yi-mechanical concussion kanye nobufakazi bokugqwala kwamakhemikhali. Uma ucingo olunwetshiwe lusetshenziswa, kufanele lube nesigaba sokuhola esanele ngokuya ngobude baso.

3.1.4 Ukugcinwa kwezinto zikagesi

Okwemizuzu. ezingozini, zonke izinto ezisetshenziswayo kumele zisetshenziswe futhi zigcinwe ngendlela elandelayo:

※ Gwema ukusebenzisa izintambo zesikhashana ezingathobeli okujwayelekile

※ Ungathinti izingxenye ze-electrophorus

※ Vimbela ukukhipha ikhebula ukuze unqamule

※ Vimbela izintambo zokudonsa zokuphakamisa imishini

※ Ungabeki into esindayo noma ecijile ezintanjeni, futhi ulawule izinga lokushisa lekhebula phakathi kwezinga lokushisa elilinganiselwe (70℃)

※ Ungasebenzi endaweni emanzi. Hlola ukuthi i-groove nezicathulo zomile yini.

※ Ungachaphazi umshini

3.1.5 Hlola isimo sokushisa somshini ngezikhathi ezithile

※ Hlola ukwahlukanisa kwezintambo ikakhulukazi amaphuzu akhishiwe

※ Ungawusebenzisi umshini ngaphansi kwesimo esibucayi.

※ Hlola ukuthi ukushintsha ukuvuza kusebenza kahle yini okungenani ngesonto.

※ Hlola umhlaba womshini ngabasebenzi abaqeqeshiwe

3.1.6 Hlanza futhi uhlole umshini ngokucophelela

※ Ungasebenzisi izinto ezisetshenziswayo (ezifana ne-abrasive, nezinye izincibilikisi) ezilimaza ukufakwa kalula lapho uhlanza umshini.

※ Qiniseka ukuthi amandla anqanyuliwe lapho uqeda umsebenzi.

※ Qiniseka ukuthi akukho monakalo emshinini ngaphambi kokuphinda usebenzise.

Uma kuphela ukulandela okushiwo ngenhla, ukuqapha kungasebenza kahle.

3.1.7 Iyaqala

Qiniseka ukuthi iswishi yomshini ivaliwe ngaphambi kokuwuvula.

3.1.8 Umuntu ongaqeqeshiwe akavunyelwe ukusebenzisa umshini noma nini.

3.2.Izingozi Ezingenzeka

3.3.1 Umshini wokuhlanganisa izinqe olawulwa yiyunithi ye-hydraulic:

Lo mshini usebenza kuphela umuntu onguchwepheshe noma abanye abanesitifiketi sokusebenza, ngaphandle kwalokho kungase kudalwe ingozi engafuneki.

3.3.2 I-Heating Plate

Izinga lokushisa eliphezulu lingafinyelela ku-270 ℃, ngakho-ke izinto ezilandelayo kufanele ziqashelwe:

------Gqoka amagilavu okuphepha

-------Ungalokothi uthinte indawo ye-heater plate

3.3.3 Ithuluzi lokuhlela

Ngaphambi kokushefa amapayipi, iziphetho zamapayipi kufanele zihlanzwe, ikakhulukazi ukuhlanza isihlabathi noma enye i-draff ekhala emaphethelweni. Ngokwenza lokhu, ukuphila onqenqemeni kungenziwa isikhathi eside, futhi kuvimbele ukuthi ama-shavings aphonswe kubantu abayingozi.

3.3.4 Uhlaka Oluyisisekelo:

Qiniseka ukuthi amapayipi noma okokufaka kulungiswe kahle ukuze uthole ukuqondanisa okulungile. Lapho uhlanganisa amapayipi, u-opharetha kufanele agcine indawo ethile emshinini ukuze kuphephe abasebenzi.

Ngaphambi kokuthutha, qiniseka ukuthi zonke izinsimbi zilungiswe kahle futhi azikwazi ukuwa ngesikhathi sokuthutha.

Landela wonke amamaki okuphepha emshinini.

Izincazelo

Umshini unohlaka oluyisisekelo, iyunithi ye-hydraulic, ipuleti lokushisisa, ithuluzi lokuhlela kanye nokwesekwa.

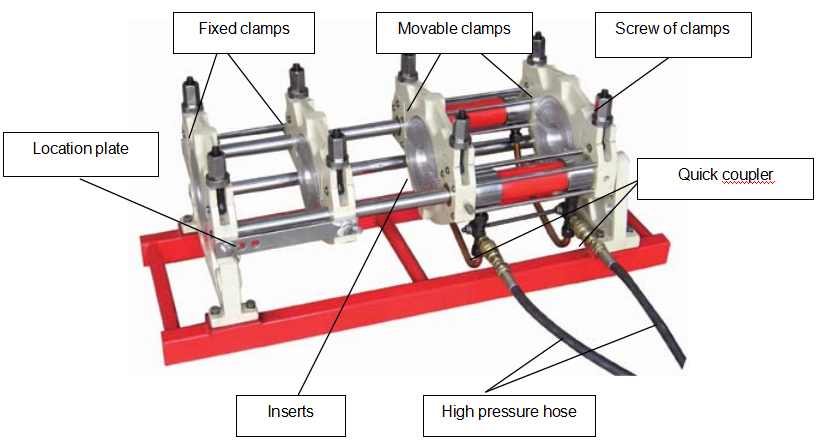

5.1 Uhlaka

5.2 Ithuluzi lokuhlela kanye ne-heater plate

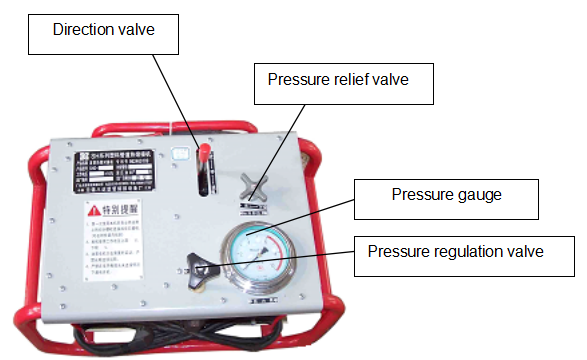

5.3 Iyunithi yeHydraulic

Umyalelo Wokusetshenziswa

6.1 Zonke izinto zokusebenza kufanele zibekwe endizeni ezinzile neyomile ukuze zisebenze.

6.2 Ngaphambi kokuthi usebenze qinisekisa lokhu okulandelayo:

u Umshini usesimweni esihle

u Amandla ahambisana nezidingo ngokuya ngomshini wokuhlanganisa izinqe

u Intambo kagesi ayiphukile noma ayigugi

u Zonke izinsimbi zivamile

u Izindwani zethuluzi lokuhlela zibukhali

u Zonke izingxenye ezidingekayo namathuluzi ayatholakala

6.3 Ukuxhumana nokuzilungiselela

6.3.1 Xhuma uhlaka oluyisisekelo kuyunithi ye-hydraulic ngama-couplers asheshayo.

6.3.2 Xhuma ulayini wepuleti lokushisisa ebhokisini likagesi kuyunithi ye-hydraulic.

6.3.3 Xhuma ulayini wepuleti lokushisisa epuleti lokufudumeza.

6.3.4 Faka izinto ezifakwayo ezifanele ukuze uzimele ngokobubanzi bangaphandle bamapayipi/izixhumi.

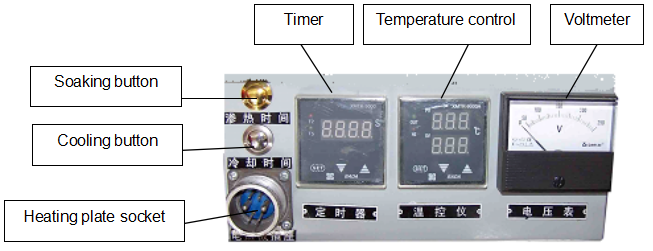

6.3.5 Ngokwezidingo zenqubo yokufaka nokushisela, setha izinga lokushisa kusilawuli sezinga lokushisa bese usetha isikhathi kusibali sikhathi. (Bheka isigaba 7 leli bhukwana).

6.4 Izinyathelo zokushisela

6.4.1 Amapayipi

Ngaphambi kokushisela, okokuqala, hlola ukuthi impahla kanye nebanga lokucindezela yikho yini edingekayo. Okwesibili hlola ukuthi akukho yini imihuzuko noma imifantu ebusweni bamapayipi/izinsimbi. Uma ukujula kwemihuzuko noma imifantu kudlula u-10% wokuqina kodonga, nquma ingxenye yemihuzuko noma imifantu. Hlanza izindawo zamapayipi ngendwangu ehlanzekile ukuze ugcine iziphetho zamapayipi zihlanzekile.

6.4.2 Ukugoqa

Beka amapayipi/izixhumi ekufakweni kohlaka futhi ugcine iziphetho ezishiselwe zibe nobude obufanayo (akunamphumela ekuhleleni nasekushisiseni ipayipi). Ipayipi eliphuma kuhlaka oluyisisekelo kufanele lisekelwe ku-axial emaphakathi yama-clamps. Bopha izikulufu zokubopha ukuze ulungise amapayipi/izixhumi.

6.4.3 Lungisa ingcindezi

Vula ngokugcwele i-valve yokulawula ukucindezela ngokuphelele, vala i-valve yokuhlola ukujikijela ngokuqinile bese uphushela phambili i-valve eqondisayo ngaleso sikhathi ulungise i-valve yokulawula ukucindezela kuze kube isilinda siqala ukunyakaza, kuleli qophelo ingcindezi ohlelweni ingcindezi yokudonsa.

Vula i-valve yokulawula ukucindezela ngokuphelele, vala i-valve yokuhlola ukujika ngokuqinile bese ucindezela phambili i-valve eqondisayo okwamanje ulungise i-valve yokulawula ingcindezi ukuze usethe ingcindezi yesistimu ilingana nokudonsa ukucindezela kwengeza i-butting pressure.

6.4.4 Ukuhlela

Vula amapayipi/izixhumo ezigcina ngemva kokujikisa ivalve yokuhlola iwashi ibheke ekupheleni. Faka ithuluzi lokuhlela phakathi kwamapayipi/amaphethelo bese uwavula, vala iziphetho zamapayipi/izifakelo ngokusebenza kuvalvu eqondisayo kuyilapho kancane jika jika jika ivalve yewashi kuze kube yilapho kuvela ukushefa okuqhubekayo ezinhlangothini zombili. Vula i-valve yokushwibeka iphikisana newashi ukuze unciphise ukucindezela, ngemva kwesikhashana vula ifreyimu, vala ithuluzi lokuhlela bese ulikhipha.

Vala amapayipi/iziphetho zokufaka bese uhlola ukuthi ziqondana yini. Ukungaqondani kahle okuphezulu akumele kudlule u-10% wokuqina kodonga, futhi kungathuthukiswa ngokuxegisa noma ukuqinisa izikulufu zezinsimbi. Igebe phakathi kokuphela kwamapayipi amabili akufanele lidlule u-10% wodonga lokujiya; uma kungenjalo amapayipi/izinsimbi kufanele zihlelwe futhi.

Isexwayiso: Ubukhulu be-shavings kufanele bube phakathi kuka-0.2 ~ 0.5 mm futhi bungalungiswa ngokulungisa ukuphakama kwama-blades amathuluzi okuhlela.

6.4.5 Ukushisisa

Sula uthuli noma ukusika endaweni ye-heater plate (Isexwayiso: Ungalimazi ungqimba lwe-PTFE endaweni yepuleti lokushisisa.), futhi uqinisekise ukuthi izinga lokushisa lifinyelele kwedingekayo.

Faka ipuleti lokushisa phakathi kokuphela kwepayipi ngemva kokuba lifinyelele izinga lokushisa elidingekayo. Vala iziphetho zamapayipi/izixhumo ngokusebenzisa ivalvu eqondisayo bese ukhuphula ingcindezi iye kumfutho othile ngokushwiba ivelufa yokulawula ingcindezi kuze kube yilapho ubuhlalu bufinyelela ukuphakama okuthile.

Guqula ivalve yokuhlola isheke ihambisane newashi ukuze unciphise ingcindezi (ingabi ngaphezu kokucindezela kokudonsa) bese ujikisa ivalve yokuhlola iwashi iye ngasekugcineni.

Cindezela inkinobho ethi “T2” , isikhathi sokucwiliswa siqala ukubala futhi isikhathi sizobala sehle siye ku-zero ngesekhondi, khona-ke i-buzzer izoba nomsindo (bona isigaba 7)

6.4.6 Ukuhlanganisa nokupholisa

Vula uhlaka bese ukhipha ipuleti lokushisa bese uvala iziphetho ezimbili ezincibilikayo ngokushesha okukhulu.

Gcina ibha ye-valve yokuqondisa endaweni eseduze imizuzu engu-2 ~ 3, beka ibha ye-valve yokuqondisa endaweni ephakathi bese ucindezela inkinobho (“T5”) ukubala isikhathi sokupholisa kuze kuphele. Kuleli qophelo, umshini uzokhipha i-alamu futhi. Yehlisa ingcindezi, khulula isikulufu sezinsimbi bese ukhipha amapayipi ahlangene.

Isikhathi Nezinga lokushisa Isilawuli

Uma enye yemingcele ishintshiwe, njengobubanzi obungaphandle, i-SDR noma impahla yamapayipi, isikhathi sokucwiliswa kanye nesikhathi sokupholisa kufanele sisethwe kabusha ngokwezinga lokushisela.

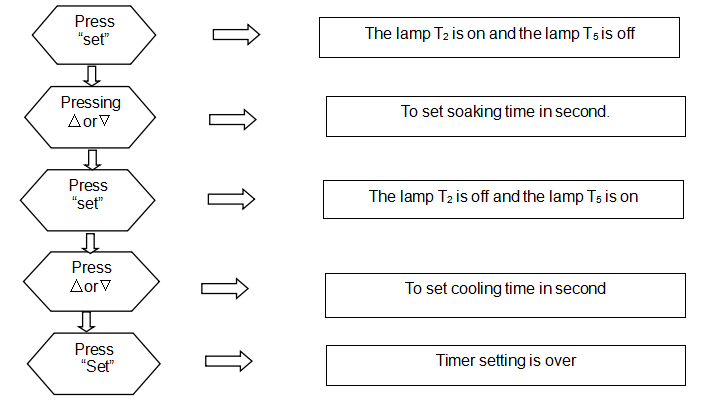

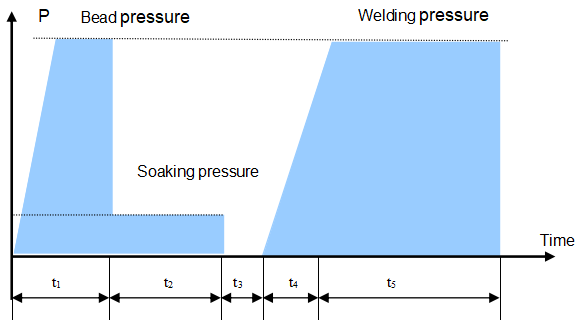

7.1 Ukusetha isikhathi

7.2 Umyalelo Wokusetshenziswa

7.3 Ukulungiselelwa kwesilawuli sezinga lokushisa

1) Cindezela okuthi “SET” imizuzwana engaphezu kwemi-3 kuze kuvele u-“sd” efasiteleni eliphezulu

2) Cindezela okuthi “∧” noma “∨” ukuze uguqule inani libe elishiwo (cindezela “∧” noma “∨” ngokuqhubekayo, inani lizohlanganisa noma likhiphe ngokuzenzakalelayo)

3) Ngemva kokusetha, cindezela u-“SET” ukuze ubuyele ekuqapheni nasekulawuleni isixhumi esibonakalayo

Ireferensi Yezinga Le-Welding (DVS2207-1-1995)

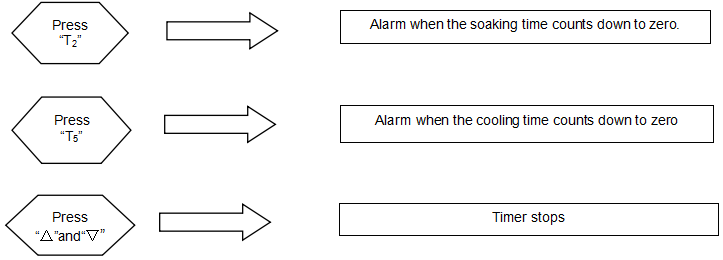

8.1 Ngenxa yomehluko kuzinga lokushisela kanye nempahla ye-PE, isikhathi nokucindezela kuyahlukahluka ezigabeni ezihlukene zokushisela. Iphakamisa ukuthi imingcele ye-welding yangempela kufanele inikezwe ngabakhiqizi bamapayipi kanye nokufakwa.

8.2 Uma kunikezwe izinga lokushisa lokushisela lamapayipi enziwe nge-PE, PP kanye ne-PVDF nge-DVS amabanga ajwayelekile ukusuka ku-180 ℃ kuya ku-270 ℃. Ukushisa kwesicelo sepuleti lokushisa kungaphakathi kwe-180℃230℃, kanye nobukhulu balo. izinga lokushisa kwamanzi lingafinyelela ku-270 ℃.

8.3 Inkomba ejwayelekile DVS2207-1-1995

| Ukujiya kodonga (mm) | Ubude be-bead (mm) | Ingcindezi yokwakha ubuhlalu (MPa) | Isikhathi sokucwilisa t2(umzuzwana) | Ingcindezi yokucwiliswa (MPa) | Ukushintsha kwesikhathi t3(umzuzwana) | Isikhathi sokwakha ingcindezi t4(umzuzwana) | Ingcindezi yokushisela (MPa) | Isikhathi sokupholisa t5(imizuzu) |

| 0 - 4.5 | 0.5 | 0.15 | 45 | ≤0.02 | 5 | 5 | 0.15±0.01 | 6 |

| 4.5-7 | 1.0 | 0.15 | 45; 70 | ≤0.02 | 5; 6 | 5; 6 | 0.15±0.01 | 6; 10 |

| 7; 12 | 1.5 | 0.15 | 70 - 120 | ≤0.02 | 6; 8 | 6; 8 | 0.15±0.01 | 10-16 |

| 12-19 | 2.0 | 0.15 | 120-190 | ≤0.02 | 8; 10 | 8; 11 | 0.15±0.01 | 16-24 |

| 19-26 | 2.5 | 0.15 | 190-260 | ≤0.02 | 10-12 | 11-14 | 0.15±0.01 | 24-32 |

| 26; 37 | 3.0 | 0.15 | 260-370 | ≤0.02 | 12-16 | 14-19 | 0.15±0.01 | 32; 45 |

| 37-50 | 3.5 | 0.15 | 370-500 | ≤0.02 | 16-20 | 19-25 | 0.15±0.01 | 45; 60 |

| 50-70 | 4.0 | 0.15 | 500-700 | ≤0.02 | 20 - 25 | 25-35 | 0.15±0.01 | 60-80 |

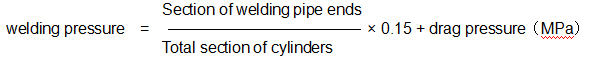

Phawula:Ingcindezi yokwakha ubuhlalu kanye nengcindezi yokushisela efomini ingcindezi yesibonisi esinconyiwe, ingcindezi yegeji kufanele ibalwe ngefomula elandelayo.

Izinkulumo:

Ukuhlaziywa Kwezinkinga Nezixazululo

8.1 Izinkinga zekhwalithi zamalunga ezivamile zihlaziya:

8.2 Izikhathi zokulondoloza kanye nokuhlola

8.2.1 Isondlo

※ I-Heating plate coating

Sicela uqaphele ukuphatha ipuleti lokushisisa. Gcina ibanga elithile kude ne-heater plate. Ukuhlanzwa kobuso bawo kufanele kwenziwe ngengaphezulu lisafudumele ngokusebenzisa indwangu ethambile noma iphepha, gwema izinto eziqhumayo ezingase zilimaze ukunamathela.

Ngezikhathi ezijwayelekile hlola kanje

1) Hlanza indawo engaphezulu usebenzisa okokuhlanza okuhwamukayo okusheshayo (utshwala)

2) Hlola ukuqiniswa kwezikulufu kanye nekhebula nesimo sepulaki

3) Qinisekisa izinga lokushisa kwamanzi ngokusebenzisa ukuskena kwe-infrared-ray

※ Ithuluzi lokuhlela

Kunconywa kakhulu ukuthi uhlale uhlanzekile ama-blades futhi ugeze ama-pulleys ngokusebenzisa okokuhlanza. Ngezikhathi ezithile, yenza umsebenzi wokuhlanza ophelele.

※ iyunithi Hydraulic

Yigcine kanje

1) Hlola njalo izinga likawoyela

2) Faka esikhundleni uwoyela ngokuphelele njalo ezinyangeni eziyisi-6

3) Gcina ithangi nesekhethi kawoyela ihlanzekile

8.2.2 Ukunakekela Nokuhlola

Ukuhlola okuvamile

| Into | Incazelo | Hlola ngaphambi kokusetshenziswa | Okokuqala inyanga | Njalo ezinyangeni eziyisi-6 | Njalo unyaka |

| Ithuluzi lokuhlela | Gaya noma shintsha i-blade Shintshanisa ikhebula uma yephukile Phinda uqinise uxhumo lwemishini |

● ● |

● |

| ● ●

|

| Ipuleti lokushisisa | Ixhume kabusha ikhebula nesokhethi Hlanza indawo yepuleti lokushisisa, gcoba kabusha ungqimba lwe-PTFE uma kunesidingo Phinda uqinise uxhumo lwemishini | ● ●

● |

● |

|

●

|

| Temp. uhlelo lokulawula | Hlola inkomba yezinga lokushisa Shintshanisa ikhebula uma yephukile |

● |

|

| ● ● |

| Uhlelo lweHydraulic | I-Checkout pressure gauge Faka esikhundleni se-seal uma iyunithi ye-hydraulic ivuza Hlanza isihlungi Qiniseka ukuthi uwoyela wanele ukuze usebenze Shintsha uwoyela we-hydraulic Faka esikhundleni uma i-hose yamafutha iphukile |

● ● ● |

|

● | ● ●

● ●

|

| Okuyisisekelo Uhlaka | Phinda uqinise izikulufu ekugcineni kwe-eksisi yozimele Fafaza upende we-antirust futhi uma kunesidingo | ●

| ●

| ●

|

● |

| Amandla Ukunikezela | Cindezela inkinobho yokuhlola yesivikeli sesekethe ukuze uqiniseke ukuthi ingasebenza ngokujwayelekile Shintshanisa ikhebula uma yephukile | ●

● |

|

● |

|

“●”………… isikhathi sokulungisa

9.3 Ukuhlaziya ukungasebenzi kahle kanye nezisombululo

Ngesikhathi sokusebenzisa, iyunithi ye-hydraulic kanye namayunithi kagesi kungase kubonakale izinkinga ezithile. Ukungasebenzi kahle okuvamile kubalwe kanje:

Sicela usebenzise amathuluzi anamathiselwe, izingxenye ezisele noma amanye amathuluzi anesitifiketi sokuphepha ngenkathi unakekela noma ushintsha izingxenye. Amathuluzi nezingxenye ezisele ngaphandle kwesitifiketi sokuphepha kwenqatshelwe ukusetshenziswa.

| Ukungasebenzi kahle kweyunithi ye-hydraulic | |||

| No | ukungasebenzi kahle | ukuhlaziya ukungasebenzi kahle | Izixazululo |

| 1 | Injini yephampu ayisebenzi |

| |

| 2 | Injini yephampu izungeza kancane kakhulu ngomsindo ongajwayelekile |

| 1. Qiniseka ukuthi umthwalo wemoto ungaphansi kuka-3 MPa 2. Lungisa noma shintsha iphampu 3. Hlanza isihlungi 4. Hlola ukungazinzi kwamandla |

| 3 | Isilinda sisebenza ngendlela engavamile |

| |

| 4 | Ukuvuza kwesilinda | 1. Indandatho yamafutha inephutha 2. Isilinda noma ipiston yonakele kakhulu | 1. Faka esikhundleni indandatho yamafutha 2. Faka esikhundleni isilinda |

| 5 | Ingcindezi ayikwazi ukunyuswa noma ukushintshashintsha kukhulu kakhulu | 1. Umnyombo we-valve yokuchichima uvaliwe. 2. Iphampu iyavuza. 3. Ukuxega okuhlangene kwepompo kuyaxegiswa noma umsele wokhiye uyashibilika. 4. I-valve yokukhulula ingcindezi ayikhiyiwe | 1. Hlanza noma shintsha umnyombo wevalvu yokugeleza ngokweqile 2. Faka esikhundleni iphampu 3. Faka esikhundleni i-joint slack 4. Khiya i-valve |

|

Ukungasebenzi kahle kwamayunithi kagesi | |||

| 1 | Umshini awusebenzi |

| 1. Hlola ikhebula lamandla 2. Hlola amandla okusebenza 3. Vula isiphazamisi sephutha eliphansi |

| 2 | Uhambo lokushintsha iphutha eliphansi |

| 1. Hlola izintambo zikagesi 2. Hlola izakhi zikagesi. 3. Hlola idivayisi yokuphepha kwamandla aphezulu |

| 3 | Izinga lokushisa elingavamile liyakhuphuka | 1. Iswishi yesilawuli sezinga lokushisa ivuliwe 2. Inzwa (pt100) ayijwayelekile. Inani lokumelana lika-4 no-5 lesokhethi yepuleti lokufudumeza kufanele libe phakathi kuka-100~183Ω 3. Induku yokushisisa ngaphakathi kwepuleti lokushisisa ayijwayelekile. Ukumelana phakathi kuka-2 no-3 kufanele kube phakathi kuka-23Ω. Ukumelana nokufakwa kwe-insulation phakathi kwekhanda lenduku yokushisa negobolondo langaphandle kufanele kube ngaphezu kwe-1MΩ 4. Uma ukufundwa kwesilawuli sezinga lokushisa kufanele kube ngaphezu kuka-300℃, okuphakamisa ukuthi inzwa yakhe ingalimala noma uxhumo luyaxega. Uma isilawuli sezinga lokushisa kufanele sibonise i-LL, okuphakamisa ukuthi inzwa ibe nesekhethi emfushane. Uma ngabe isilawuli sezinga lokushisa kufanele sibonise i-HH, okuphakamisa ukuthi ukujikeleza kwenzwa kuvuliwe. 5. Lungisa izinga lokushisa ngenkinobho etholakala kusilawuli sezinga lokushisa.

| 1. Hlola ukuxhumeka koxhumana nabo 2. Faka esikhundleni inzwa

3. Faka esikhundleni ipuleti lokushisisa

4. Faka esikhundleni isilawuli sezinga lokushisa

5. Bheka izindlela zokusetha izinga lokushisa 6. Hlola bese ubuyisela oxhumana nabo uma kunesidingo |

| 4 | Ukulahlekelwa ukulawula lapho ushisisa | Ukukhanya okubomvu kuyakhanya, kodwa izinga lokushisa lisakhuphuka, lokho kungenxa yokuthi isixhumi sinephutha noma amalunga 7 no-8 awakwazi ukuvula lapho ethola izinga lokushisa elidingekayo. | Faka esikhundleni isilawuli sezinga lokushisa

|

| 5 | Ithuluzi lokuhlela alizungezi | Ukushintsha okulinganiselwe akusebenzi noma izingxenye zemishini zethuluzi lokuhlela ziyasikwa. | Faka esikhundleni iswishi yomkhawulo wethuluzi lokuhlela noma i-sprocket encane |