Ukusheshisa Imiklamo Yepayipi: Izinzuzo Zokushisela Okusheshayo Kwezisetshenziswa Zepayipi Lepulasitiki

Isingeniso ku-Fast Welding Plastic Pipe Equipment

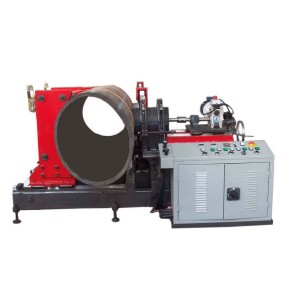

Imishini yamapayipi epulasitiki yokushisela esheshayo ihlanganisa amathuluzi ahlukahlukene kanye nemishini eyakhelwe ngokukhethekile ukuthuthukisa isivinini senqubo yokushisela kuyilapho kuqinisekiswa amalunga aqinile futhi ahlala isikhathi eside. Kusukela emishinini emisha yokuhlanganisa izinqe kuye kumayunithi asezingeni eliphezulu kakhulu e-electrofusion, lesi sisetshenziswa siklanyelwe ukusethwa okusheshayo, imijikelezo yokushisela esheshayo, kanye nezikhathi zokupholisa ezincane, kunciphisa kakhulu izikhathi zephrojekthi.

Izici Eziyinhloko Nezinzuzo

●Isivinini: Yenzelwe ukushisela ngokushesha, inciphisa kakhulu isikhathi esidingekayo ekuhlanganyeleni ngakunye.

●Ukunemba: Izinhlelo zokulawula ezithuthukisiwe ziqinisekisa ukusetshenziswa kokushisa okunembile nokucindezela, okuholela ekushiseleni kwekhwalithi ephezulu.

●Ukusebenza kahle: Iqondisa yonke inqubo yokushisela, kusukela ekulungiseleleni kuze kube sekupheleni, ithuthukisa ukusebenza kahle kwephrojekthi iyonke.

●Ukuguquguquka: Ifanele izinhlobonhlobo zamasayizi wamapayipi nezinto zokwakha, iqinisekisa ukusebenza okubanzi kuwo wonke amaphrojekthi.

Izinhlelo zokusebenza

Imishini yamapayipi epulasitiki yokushisela ibaluleke kakhulu ezimeni ezahlukahlukene, okuhlanganisa:

●Ingqalasizinda yamanzi nendle: Ukufakwa nokulungiswa okusheshayo kwezintambo zamanzi nezokukhucululwa kwendle, kunciphisa ukuphazamiseka.

●Ukusabalalisa Igesi: Ukwakhiwa okuphumelelayo kwamanethiwekhi amapayipi egesi, ukuqinisekisa ukuphepha nokwethembeka.

●Izicelo zezimboni: Ukusetha okusheshayo nokugcinwa kwamapayipi enqubo ezindaweni zokukhiqiza, izitshalo zamakhemikhali, nokunye.

●Izinsiza ezingaphansi komhlaba: Ukufakwa okusheshayo nokuthembekile kwamapayipi okuxhumana ngocingo nezinkonzo zikagesi.

Ukukhetha Isisetshenziswa Sephayiphu Sepulasitiki Welding Esisheshayo Esisheshayo

Ukukhetha ithuluzi lepayipi le-welding esheshayo yepulasitiki kuhilela ukucatshangelwa okuningi:

●I-Pipe Material kanye nobubanzi: Khetha okokusebenza okuhambisana nezinhlobo ezithile zamapayipi epulasitiki kanye nebanga lamadayamitha kumaphrojekthi akho.

●I-Welding Technique: Nquma phakathi kokuhlanganiswa kwezinqe, i-electrofusion, noma ezinye izindlela zokushisela ngokusekelwe kuhlelo lokusebenza nezimfuneko.

●Ukuphatheka: Kumaphrojekthi adinga ukuhamba, cabangela amamodeli angasindi nahlangene angadela isivinini noma ikhwalithi.

●Isixhumi esibonakalayo somsebenzisi: Khetha amamodeli anezilawuli ezinembile kanye nesistimu yempendulo ecacile ukuze uhambise inqubo yokushisela ngokuqhubekayo.

Amathiphu Okusebenzisa Ngokuphumelelayo

●Ukuqeqeshwa Okufanelekile: Qinisekisa ukuthi abaqhubi baqeqeshwe ngokwanele ekusebenziseni okokusebenza nasezicini zokuphepha ukuze kwandiswe izinzuzo zayo zesivinini.

●Isondlo Esijwayelekile: Gcina futhi uhlole imishini yakho yokushisela ukuze uyigcine isesimweni esifanele sokusebenza okusheshayo, okuthembekile.

●Izinyathelo Zokuphepha: Landela zonke izimiso zokuphepha ezinconyiwe ukuze uvikele opharetha futhi uqinisekise inqubo yokushisela ebushelelezi.

●Ukulungiselela Okufanelekile: Lungiselela kahle iziphetho zamapayipi nezindawo zokusebenza ukuze uhambisane nesivinini semishini yakho yokushisela.

Isiphetho

Imishini yamapayipi epulasitiki eshisela ngokushesha imele inguquko ebalulekile ekwakhiweni nasekulungisweni kwamapayipi, okwenza amaphrojekthi aqhubeke ngesivinini esingakaze sibonwe ngaphandle kokudela ubuqotho noma ukuqina. Ngokuhlanganisa la mathuluzi athuthukisiwe ekuhambeni kwakho komsebenzi, ungakwazi ukuzuza ukonga isikhathi esibalulekile, unciphise izindleko zabasebenzi, futhi uthuthukise izikhathi zokushintsha iphrojekthi. Kungakhathaliseki ukuthi iphrojekthi yengqalasizinda emikhulu noma emincane, ukulungiswa okuzwela isikhathi, okokusebenza kokushisela okusheshayo kusethelwe ukuba kube yimpahla ebaluleke kakhulu embonini yokushisela amapayipi epulasitiki.